Dimatec’s bit and reaming shell products are typically provided with features to protect them from damage and premature wear while in-service.

The application of hard-metal armour coating strips to the steel body of most types of diamond tools is available and is recommended when drilling in highly abrasive formations. This optional feature aids in the prevention of premature erosion of the steel tool body. In most cases, three equally spaced strips are applied to the steel tool shank. The approximate dimensions of each strip is 12mm (0.50 inch) wide by 0.5mm (0.02 inch) thick. The length of the strips varies according to the type of tool and typically covers the area indicated in the illustration below.

The armour coating strips are composed of micron-sized tungsten-carbide particles that are suspended in a metal alloy. They are applied using a plasma spray technique. Due to the elevated fusion temperatures that are required for this process, the application of hard-metal strips on some thin-wall diamond tools is not possible.

Armour coating strips are provided only on request. Pricing for this option varies by tool type. Contact Dimatec for a quotation.

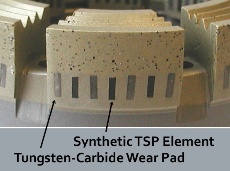

As both the hole diameter and core diameter dimensions that are cut by a core bit must be consistent, the inside and outside gauging sections on all Dimatec impregnated diamond bit crowns are embedded with wear-resistant elements to preserve these critical dimensions. The consistency of the outside set diameter is critical in order to maintain interchangeability between different bits and other in-hole tooling while the consistency of the inside set diameter is critical for effective core capture by the core barrel system.

Unless otherwise specified, all impregnated core bits produced by Dimatec have their inside and outside set diameter gauging sections set with a combination of seismic grade tungsten-carbide wear pads and thermally stable polycrystalline (TSP) diamond elements in an alternating pattern as shown in the photograph below. Note that due to physical space constraints, the tungsten-carbide wear pad setting is usually omitted on thin-wall impregnated diamond core bits with kerf widths of 7.6 mm (0.30 inch) or less.

All bits, reaming shells, casing shoes and stabilizing products are individually packed in protective cardboard boxes. These boxes are then packed into easy to handle cardboard cartons that have a maximum weight of 25 kg (55 lbs.) and conform to most airline unit weight restrictions. On request, larger quantities of these products may be packed into wooden transport crates that are suitable for handling by fork lift trucks.

Customer specified packaging requirements are accommodated by contacting Dimatec Inc. directly.

In compliance with EU (European Union) restrictions on wooden packaging materials, all wood materials used by Dimatec to construct pallets, skids and shipping containers are either pressure treated, heat treated or kiln dried.