When a diamond impregnated core bit is removed from the drill-hole after use, the resulting wear pattern on the bit face is an important source of information for the operator. By “reading” the bit face, the operator can frequently troubleshoot problems by simply altering the drill’s operating parameters or by changing the bit to a matrix type or waterway configuration that is better suited to the ground conditions.

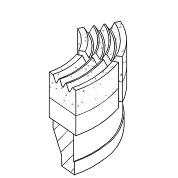

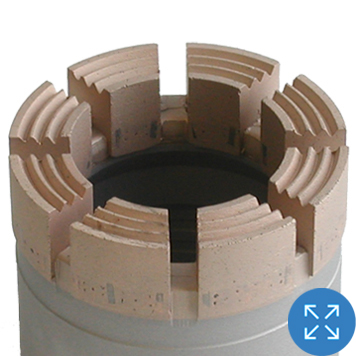

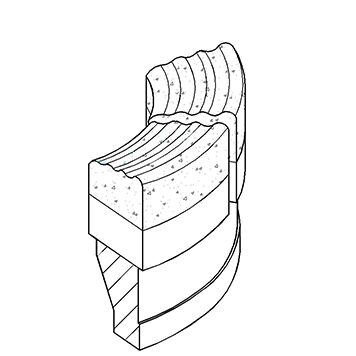

For reference purposes, this graphic illustrates the appearance of a new, unused diamond impregnated core bit crown.

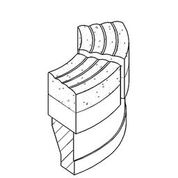

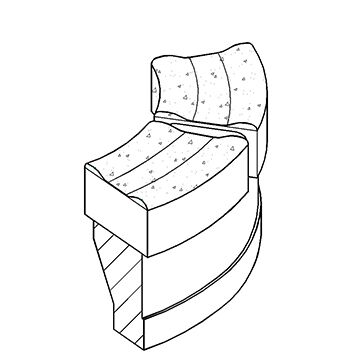

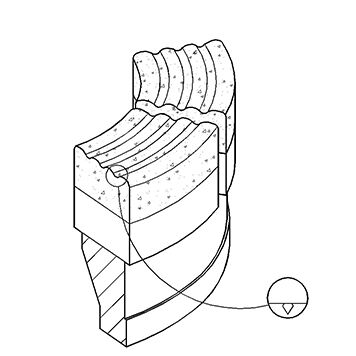

This is the typical mid-life wear pattern on a properly used diamond impregnated core bit. The face should be relatively flat with slightly chamfered sides.

The full depth of diamond impregnation has been evenly consumed.

Possible causes and solutions:

Possible causes and solutions:

Possible causes:

This wear pattern frequently results from the use of a rate of penetration that is too high for the rotational speed being used (overfeeding). This wear pattern is also caused by “grinding core”.

Possible causes and solutions:

In this wear pattern, the metal-bond matrix abrades away before the diamond crystals have become worn. As there is insufficient metal-bond matrix material to support the over-exposed diamond crystals on the bit face, the diamonds are released from the matrix material prematurely. This usually results in low bit life. Possible causes and solutions:

In this condition, the diamond crystals on the bit face have become completely embedded in the metal-bond matrix. If possible, grit blast the bit face with abrasive media to re-expose the diamond crystals. Try drilling with a slower rotational speed and/or a lower in-hole fluid circulation rate in an effort to cause the metal-bond matrix to abrade at a higher rate. This will cause the diamond crystals to become exposed more readily. If the bit face glazes repeatedly, change to a softer (higher number) Dimatec matrix type.

This condition is the result of a significant loss of fluid circulation across the bit face. Possible causes for this condition include:

In cases in which the matrix type and waterway configuration have been correctly selected, a diamond impregnated core bit should drill steadily with an even wear pattern until the matrix layer has been totally consumed. At this point, the circulating pump pressure will normally increase due to the fluid restriction caused by the diminished waterway canal depth on the bit face.

If the matrix type and/or waterway configuration has not been exactly matched to the formation conditions, it may become necessary to sharpen the bit face if the rate of penetration becomes unacceptably low. A decrease in penetration rate is usually caused by the diamond crystals on the bit face becoming blunt. The metal bond matrix is probably too hard for the formation conditions and will not erode at a controlled rate to expose new layers of diamond crystals. If possible, change to another Dimatec bit with:

If it is not possible to change the bit, it will be necessary to sharpen the bit face using one of the following methods. Bit sharpening techniques should only be used when absolutely necessary as they can have an adverse effect on overall bit life if they have been improperly performed.

Remove the bit from the drill hole and grit blast the bit face with an abrasive media such as aluminum-oxide or silicon-carbide powder. If grit blasting equipment is not available on site, carefully use a tapping action with the edge of a flat file to roughen the surface of the bit face.

With the bit on the bottom of the drill hole and with the drill string rotating, reduce the rotational speed to about 50% to 75% of the normal rotational speed. Try to maintain a constant rate of penetration for a distance of 6 to 50 mm (0.25 to 2 inch) allowing the bit load to gradually increase and then suddenly decrease thus indicating that the bit face has sharpened and should now cut freely. IMPORTANT: It is imperative that at the instant this sharpening (bit load decrease) occurs, the applied bit load must be decreased and the rotational speed must be increased to their original values. Failure to make this adjustment will result in further stripping and could cause a premature failure of the bit crown.

When drilling in extremely hard formations with a high silicate content, it may be necessary to slightly reduce the fluid circulation rate below recommended values in order to maintain bit sharpness.

THE FLUID CIRCULATION MUST NEVER BE COMPLETELY CUT-OFF TO A BIT ROTATING UNDER LOAD AND IS NOT AN ACCEPTABLE METHOD OF SHARPENING ANY DIAMOND IMPREGNATED BIT.