Diamond impregnated casing shoes are recommended for use in the majority of applications. These products include the economical D-Series type as well as the more robust Super Duty type. Both types are available as either casing shoes (to connect to casing tubes) or rod shoes (to connect to wireline drill rods).

In addition, thick kerf, heavy duty diamond impregnated casing bits are available for use in the most difficult overburden conditions. These casing bits are available in several common sizes for use with standard casing tubes. On request, they may also be supplied with a wireline drill rod thread connection.

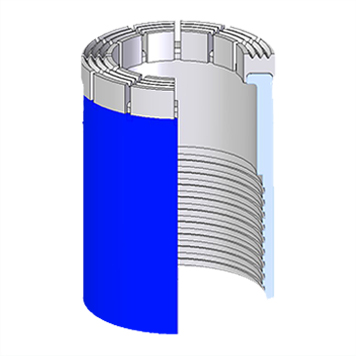

Super Duty diamond impregnated casing shoes / rod shoes are available for use with all DCDMA casing tube sizes as well as a limited number of wireline drill rod sizes. Super Duty casing shoes and rod shoes are manufactured with a more aggressive matrix layer than the D-Series type. As such, they are intended for use in thicker overburden layers that may contain boulders.

Super Duty casing shoes / rod shoes are supplied with a:

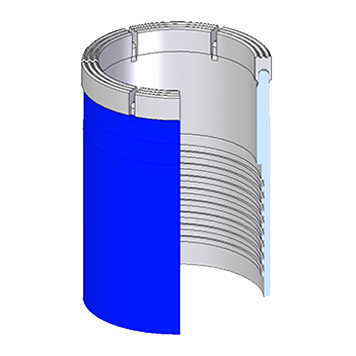

This economical diamond impregnated casing shoe / rod shoe is available for use with all DCDMA and metric casing tube sizes as well as a limited number of wireline drill rod sizes. The D-Series casing shoe / rod shoe is intended for use in light duty applications in which casing tubes are to permanently remain in the drill hole.

D-Series casing shoes / rod shoes are supplied with a:

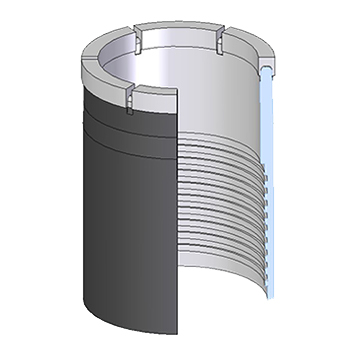

Dimatec’s diamond impregnated Casing Bits are intended for use in the most difficult overburden conditions. They feature a thick-kerf wireline core bit crown that is mounted on a steel body with a standard casing tube thread connection. All Dimatec Casing Bits are supplied with a V-ring profile and either a 9 mm (0.35 inch) or 12 mm (0.47 inch) depth of diamond impregnation. They are normally available with any of the Dimatec D3, D4 or D7 bit matrices. Other Dimatec matrix types are available on request.

The kerf thickness of a Dimatec Casing Bit crown will not allow a corresponding size core bit to pass directly through the face of the tool. It is necessary therefore, to drill through the Casing Bit crown once the casing has been set into the bedrock.