This group of products use tungsten-carbide as their cutting media. They are intended for use in very soft and granular conditions.

Two types of tungsten-carbide casing shoes are offered:

Both types are available for most types of DCDMA casing tubes as well as a limited number of wireline drill rods.

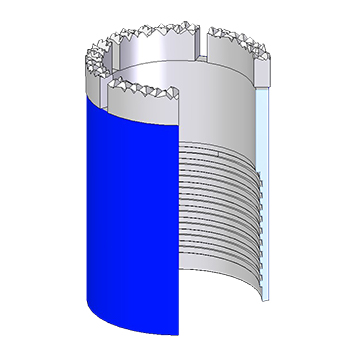

These tools are set with large, rectangular-shaped tungsten-carbide elements that are physically embedded into the crown of the tool. The bit face has an aggressive saw-tooth pattern with integral canal-type waterways. The tool crown itself is composed of a tough, wear-resistant metal-bond matrix material. The gauge diameters of the crown are also heavily set with tungsten-carbide wear pads.

The application of this type of tool is primarily in geotechnical soil investigation or for advancing casing tubes through overburden layers that are composed mainly of clay, sand, gypsum or soft shale.

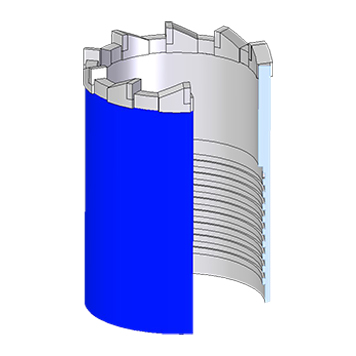

The cutting media that is used in this type of tool is crushed tungsten-carbide chips. These chips are suspended in a metallic alloy is fused to a steel tool body. Typically, the tungsten-carbide chips have a granular size of 2 to 5 mm (0.08 to 0.20 inch) and have a totally random orientation within the tool crown. The face profile is somewhat irregular and the waterways are of the standard internal discharge canal-type design.

These tools have considerably more cutting edges than the saw-tooth variety and as such, have a wider range of application that includes slightly harder sedimentary formations.

Carbide chip casing shoes are similar to diamond impregnated casing shoes in that the tool crown is composed of several layers of cutting media. The tool face regenerates itself with new cutting edges by wearing away the metallic alloy during operation to continually expose new layers of carbide chips until the tool crown is consumed.