Geotechnical core bits are commonly applied in both the mineral exploration and civil engineering sectors. They are designed for use in drilling the softer, abrasive, and unconsolidated sedimentary formations that are not effectively drilled by diamond impregnated core bits. These formations may range from very soft clay, gypsum or talc up to and including harder types of sandstone.

Unlike diamond impregnated bits, these products feature a single layer of cutting media that are either embedded or mounted in a tough, wear-resistant matrix-body.

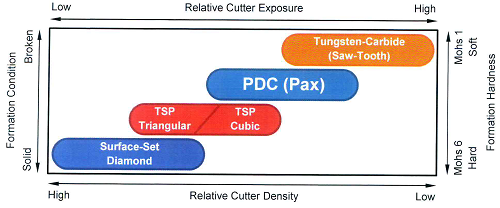

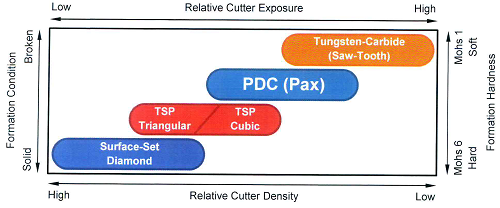

Four different types of cutting media are offered in this product range. The primary difference between these types are the:

- Cutting media material (natural diamond, synthetic diamond or tungsten-carbide),

- Extent of cutter exposure,

- Cutting media density (number of cutting edges per unit bit face area).

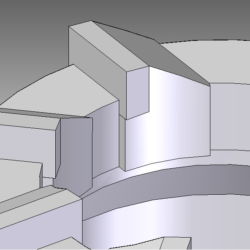

TSP

Thermally Stable Polycrystalline cutting media for use in drilling slightly fractured, moderately hard formations with a Mohs hardness of 3 to 5.

Read More >

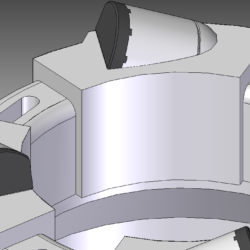

PDC (Pax)

Polycrystalline Diamond Compact cutting media for use in drilling unconsolidated, soft to moderately hard formations with a Mohs hardness of 2 to 4.

Read More >

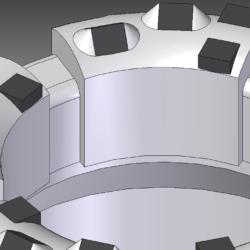

Tungsten-Carbide

Effective when drilling very soft or granular formations. Also recommended for use in milling through steel fragments in existing drill holes.

Read More >