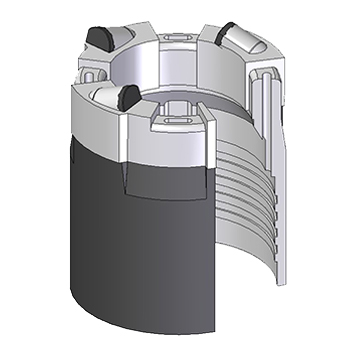

Pax-set core bits are supplied with large, cylinder shaped synthetic polycrystalline diamond compact (PDC) cutter elements that are mounted in a matrix-body bit crown. The cutter elements consist of micron-sized synthetic diamond particles that are mounted onto a tungsten-carbide substrate.

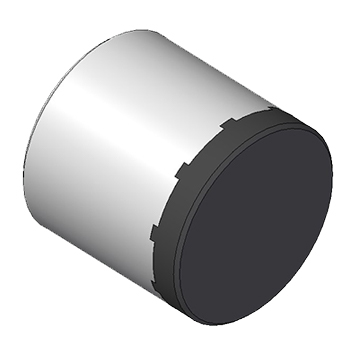

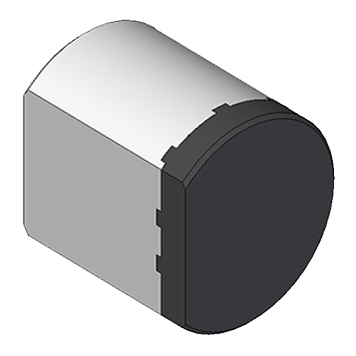

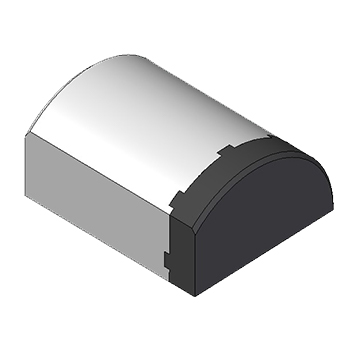

Most sizes of Dimatec Pax-set core bits are available with one or more of the following three standard cutter types. The R-Pax style uses a fully round element while the T-Pax and H-Pax styles use cylindrical cutters that have been truncated to provide stronger gauge definition.

For heavy duty applications, the T-Pax style is recommended in place of the H-Pax style as T-Pax cutters are physically larger and as such possess a larger surface area for anchoring within the bit crown matrix body.

The gauge diameter surfaces of these bits are set with a combination of TSP elements and tungsten-carbide wear pads.

Pax-set core bits are recommended for use in softer unconsolidated formations with a Mohs hardness in the range of 2 to 3. Typical formation types include (but are not limited to):

In order to efficiently eject the large, often sheared cuttings that are generated by Pax-set bits, most are supplied with the slot face discharge (SFD) waterway configuration. In addition, most Pax-set bit designs include junk slots on the outside diameter to promote cuttings ejection.

The information contained in this section is provided as a basic technical guide for the field application of Dimatec core drilling bits. To use these products successfully, it is necessary for the driller to provide some control over the three primary operating parameters which are:

The data provided here is intended as a basic guideline for the selection of the appropriate tools for your job and the normal operating requirements for their application. As drilling conditions and the capabilities of drilling equipment vary considerably from site to site, it is impossible to define absolute application recommendations. Some experimentation on the part of the user may be required as operating parameter values outside of the ranges suggested here may be applicable to your particular conditions. Technical support is available by contacting Dimatec directly.