TSP bits use Thermally Stable Polycrystalline diamond elements as their primary cutting structure. These elements are composed entirely of micron-sized synthetic diamond particles that are formed into the shape of either a triangular or cubic prism. In many respects, this type of bit is similar in design to the surface-set diamond type with the following differences:

In all cases, the TSP diamond elements are permanently embedded in a tough, wear resistant powdered metal matrix body that is fused to a steel tool body.

TSP bits are recommended for use in generally abrasive formations with a Mohs hardness in the range of 3 to 5.

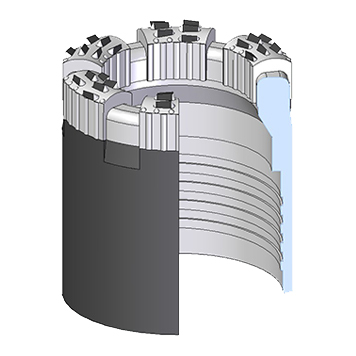

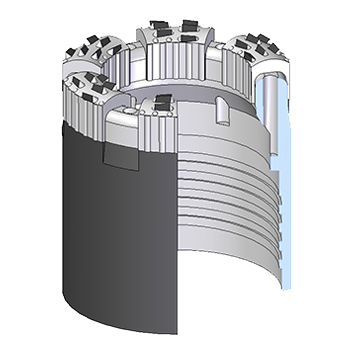

This type of bit is a hybrid modification of the surface-set diamond type. It features a relatively dense setting of triangular TSP elements that is augmented with ‘P2’ Grade natural drill diamond set on the bit face adjacent to the outside and inside gauge diameters.

Triangular TSP bits are recommended for use in consolidated to slightly fractured formations with a Mohs hardness in the range of 4 to 5. Typical formation types include (but are not limited to):

The dimensions of the TSP cutting elements that are used in this style of bit typically have a 4mm edge length with a thickness of 2.7mm.

All triangular TSP core bits are provided with a semi-round (Style ‘W’) bit crown profile.

Available waterway configurations include:

This waterway configuration feeds circulating fluid from the inside diameter across the bit face to the outside diameter through wide, wedge-shaped waterway canals. The wider canals are necessary to promote the ejection of the larger cuttings that are typically produced by TSP bits. The TXW configuration is the standard for triangular-TSP core bits and is recommended for use in most applications. Higher circulation pump rates should be applied for effective performance.

Recommended for use when drilling in relatively soft, unconsolidated formations and/or when using triple-tube wireline core barrel systems. The circulation fluid passes through cylindrical ports that have been moulded into the bit face. This results in minimal core wash and thus reduces the potential for undesirable core sample erosion. By design, face discharge bits develop relatively low fluid pressure across the bit face, even when higher circulation rates are applied.

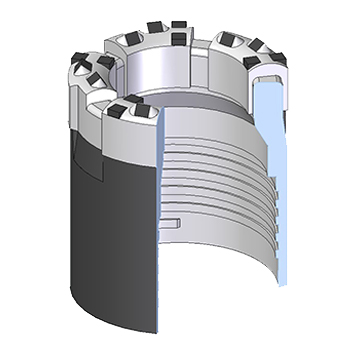

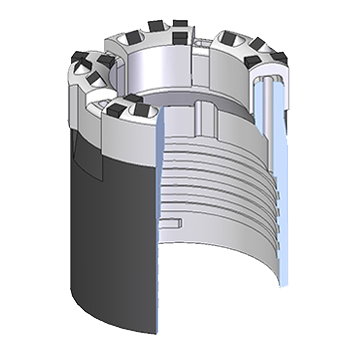

This type of bit is set with cube-shaped TSP elements. These elements are larger in size than the triangular TSP elements and as such, provide a greater degree of cutter protrusion. The setting density on a cubic-TSP core bit is somewhat lower than that of a comparably sized triangular-TSP core bit.

Cubic TSP bits are recommended for use in unconsolidated formations with a Mohs hardness in the range of 3 to 4. Typical formation types include (but are not limited to):

The dimensions of the TSP cutting elements that are used in this style of bit typically have a 5mm edge length.

All cubic TSP core bits are provided with a semi-round (Style ‘W’) bit crown profile. Available waterway configurations include:

This waterway configuration feeds circulating fluid from the inside diameter across the bit face to the outside diameter through wide, wedge-shaped waterway canals that in most cases, include external junk slots. The wider canals and junk slots are necessary to promote the ejection of the larger cuttings that are typically produced by TSP bits. The TXW configuration is the standard for cubic-TSP core bits and is recommended for use in most applications. Higher circulation pump rates should be applied for effective performance.

Recommended for use when drilling in relatively soft, unconsolidated formations and/or when using triple-tube wireline core barrel systems. The circulation fluid passes through slot-shaped ports that have been moulded into the bit face. This results in minimal core wash and thus reduces the potential for undesirable core sample erosion. By design, slot face discharge bits develop relatively low fluid pressure across the bit face, even when higher circulation rates are applied.

The information contained in this section is provided as a basic technical guide for the field application of Dimatec core drilling bits. To use these products successfully, it is necessary for the driller to provide some control over the three primary operating parameters which are:

The data provided here is intended as a basic guideline for the selection of the appropriate tools for your job and the normal operating requirements for their application. As drilling conditions and the capabilities of drilling equipment vary considerably from site to site, it is impossible to define absolute application recommendations. Some experimentation on the part of the user may be required as operating parameter values outside of the ranges suggested here may be applicable to your particular conditions. Technical support is available by contacting Dimatec directly.