Tungsten-carbide core bits are provided with large sintered cutters that are mounted on the bit crown in a saw-tooth arrangement. Alternatively, they may also be provided with a tool crown that is composed entirely of granular tungsten-carbide chips. Tungsten-carbide core bits are recommended for use in coring clay, sand and soft overburden where no penetration into bedrock is expected.

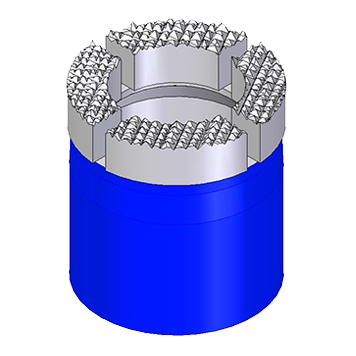

The cutting media used in this type of bit is crushed tungsten-carbide chips that are suspended in a metallic alloy that is fused to the steel body of the tool. Typically, these tungsten-carbide chips have a granular size of 2 to 5 mm (0.08 to 0.20 inch). They have a totally random orientation within the bit crown. The face profile is somewhat irregular and the waterways are of the standard canal type.

This type of bit has considerably more cutting edges than the saw-tooth type and as such, has a wider range of application that includes slightly harder sedimentary formations. Carbide chip bits are also frequently used to clean steel fragments out of existing drill holes.

Carbide chip bits are similar to diamond impregnated core bits in that the bit crown is composed of several layers of cutting media. The bit face regenerates itself with new cutting edges by wearing away the metallic alloy to continually expose new layers of carbide chips until the bit crown is fully consumed.

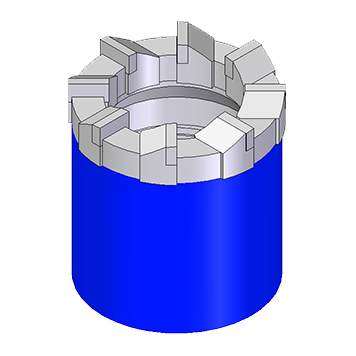

These bits are set with large, rectangular-shaped tungsten-carbide elements that are physically embedded into the crown of the tool. The bit face has an aggressive saw-tooth pattern with integral canal type waterways (illustrated). Optional cylindrical face discharge ports are also available on wide-kerf bits for use on wireline core barrel systems.

The bit crown itself is composed of a tough, wear resistant metal-bond matrix material. The gauge diameters of the tool crown are heavily set with tungsten-carbide wear pads.

The application of this type of bit is primarily for geotechnical soil investigation or for core drilling in overburden layers that are composed mainly of clay, sand, gypsum or soft shale.

The information contained in this section is provided as a basic technical guide for the field application of Dimatec core drilling bits. To use these products successfully, it is necessary for the driller to provide some control over the three primary operating parameters which are:

The data provided here is intended as a basic guideline for the selection of the appropriate tools for your job and the normal operating requirements for their application. As drilling conditions and the capabilities of drilling equipment vary considerably from site to site, it is impossible to define absolute application recommendations. Some experimentation on the part of the user may be required as operating parameter values outside of the ranges suggested here may be applicable to your particular conditions. Technical support is available by contacting Dimatec directly.