Hole opener tools are used to enlarge existing drill holes. They are comprised of a diamond impregnated bit plus one or more accessories that complete the tool assembly.

Where the amount of material that is to be removed to achieve the desired hole size is relatively thin, then an Integral Hole Opener Bit is recommended for use.

Where the amount of material that is to be removed to achieve the desired hole size is relatively thick or where the starting drill hole has a large diameter, then a Pilot Reamer Tool is recommended for use.

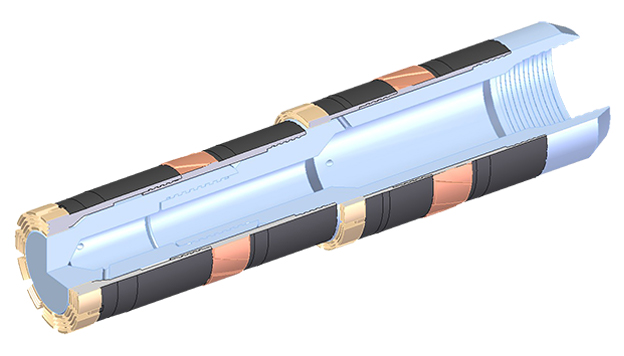

These rotary tool assemblies are used to enlarge holes that require thicker amounts of material to be removed between the existing and desired drill hole diameters. They are also recommended for use on larger diameter holes such as those in which the existing hole diameter exceeds 100 mm (3.94 inches).

The tool assembly itself consists of an inner drive body and end cap. A standard core bit and reaming shell of the size used to create the existing hole is fitted onto the leading end of the inner assembly. This bit and reaming shell will guide the tool down the existing drill hole. A second larger diamond impregnated bit and reaming shell are fitted to the outside of the inner assembly to drill out the formation to the new desired hole size.

These are customized tools that are designed to suit specific customer requirements for hole opening. In many cases, the drive end thread connection can be designed to allow the tool assembly to attach to a customer specified drill string.

Drill holes in virtually any formation type can be successfully enlarged as the outer bits are available with any of the standard Dimatec matrix types.

The individual components of these tools are sold separately. Contact the Dimatec sales team for tool recommendations and availability.

These bits are typically used to enlarge smaller gauge size holes that require relatively thin amounts of material to be removed between the existing and desired drill hole diameters. For example, these tools are recommended for enlarging standard hole gauges such as BWL to NWL or 76 mm to 86 mm.

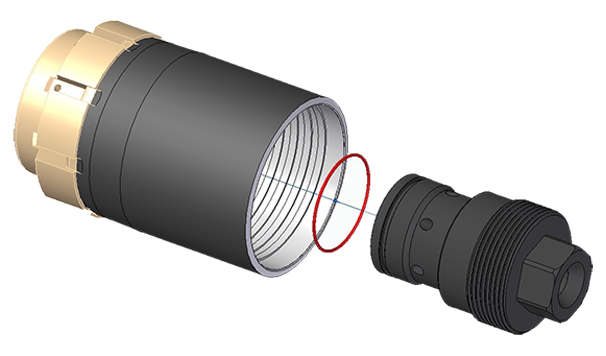

The bit crown features an integral pilot nose that guides the tool down the existing hole as the bit drills out the formation material to enlarge the hole to the desired size. The pilot nose feature ensures concentricity between the existing and new hole diameters.

Drill holes in virtually any formation type can be successfully enlarged as these bits are available with any of the standard Dimatec matrix types.

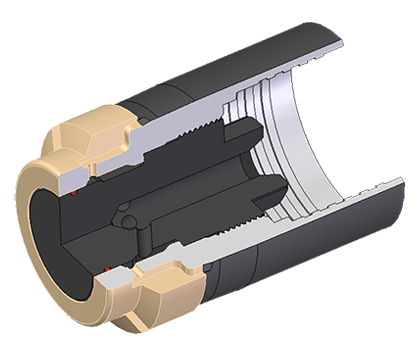

Along with the bit itself, the tool assembly consists of an internal bypass plug and O-ring.

The bypass plug directs circulation fluid from the interior of the assembly through side discharge ports in the bit crown. This both cools the pilot nose and flushes away the cuttings. The bypass plug is a re-usable part that can be transferred from one bit to another of the same type. It is designed to be installed/removed using a standard hex socket and ratchet wrench. The O-ring should be replaced whenever the bypass plug is assembled into a new bit. This will ensure that there is no loss of circulation fluid pressure through the bit crown.

In order to provide further stabilization while drilling, the tool assembly is designed to be threaded directly onto a standard reaming shell of the new larger hole size.

The individual components of these tools are sold separately. Please contact the Dimatec sales team for tool recommendations and availability.