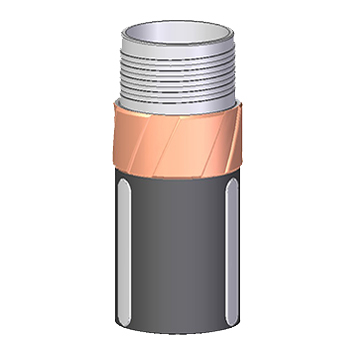

The Dimatec RS-5 reaming shell is manufactured with a full matrix body gauge ring that is cast onto the steel tool body. This ensures maximum bond strength and tool integrity. In addition, the RS-5 reaming shell’s gauge ring includes spiral waterway canals that both effectively clear the bit’s cuttings while providing full 360° hole contact.

The cutting media that is used on all RS-5 reaming shell products is a combination of synthetic diamond grit, thermally stable polycrystalline (TSP) synthetic diamond elements and tungsten-carbide wear pads. These materials are cast into a tough, abrasion resistant matrix body. Unlike some reaming shell designs that employ natural industrial diamond particles, Dimatec’s RS-5 reaming shells are set entirely with synthetic diamond materials that have known engineering properties. This feature makes the RS-5 reaming shell well suited for use on drilling projects in which the potential for contamination by natural diamond crystals is considered objectionable.

Dimatec RS-5 reaming shells are suitable for use in all formation conditions ranging from broken and abrasive to consolidated and non-abrasive.

These economical diamond-set reaming shells are available for use on most conventional and wireline core barrel assemblies of up to 152 mm (6 inches) in diameter. They are designed and manufactured to conform to the standard dimensional requirements for reaming shells used with all common core barrel types.

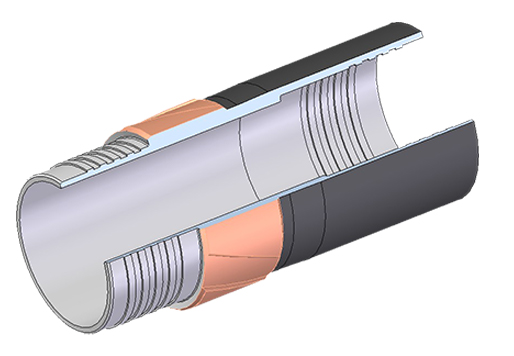

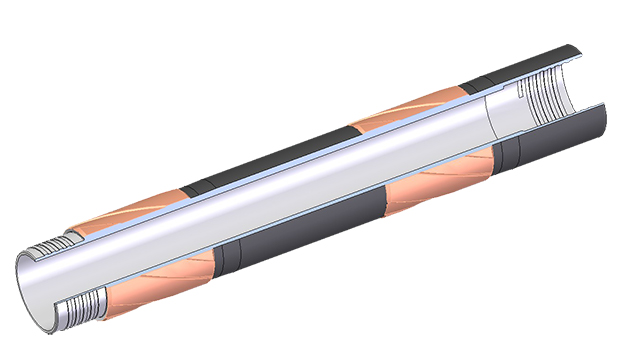

Dimatec’s long ring, extended length reaming shells are available for most wireline core barrel assemblies in the AWL (Ø 48.0 mm) to PWL (Ø 122.6 mm) size range. Their purpose is to assist in minimizing the degree of drill hole angular deviation in target or deep hole drilling applications.

All Dimatec “long ring” reaming shells have a 254 mm (10 inch) overall length that features a single, extended length diamond-set RS-5 type matrix body gauge ring. As “long ring” reaming shells are physically longer than the corresponding standard length version, an appropriate inner tube extension is required to compensate for the difference in overall reaming shell length.

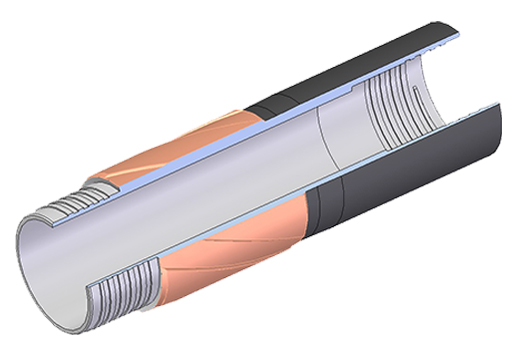

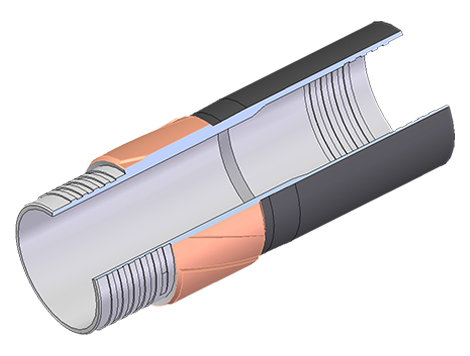

Dimatec’s double ring, extended length reaming shells are available for wireline core barrel assemblies in the BWL (Ø 60 mm) to HWL (Ø 96 mm) size range. These tools provide maximum stabilization and assist in minimizing the degree of drill hole angular deviation in target or deep hole drilling applications.

All Dimatec “double ring” reaming shells have a 467 mm (18.38 inch) overall length that features two, extended length diamond-set RS-5 type matrix body gauge rings. As “double ring” reaming shells are physically longer than the corresponding standard length version, an appropriate inner tube extension is required to compensate for the difference in overall reaming shell length.

Two variants of the double ring reaming shell are available, depending on customer preference:

These are diamond set tools that are used in place of the adapter coupling on wireline core barrel assemblies in the AWL (Ø 48.0 mm) to PWL (Ø 122.6 mm) size range. Unlike an adapter coupling however, the gauge ring on these tools is set to full hole gauge diameter. The purpose of the backend reamer is to provide additional stabilization behind the core barrel outer tube in straight-hole drilling applications.

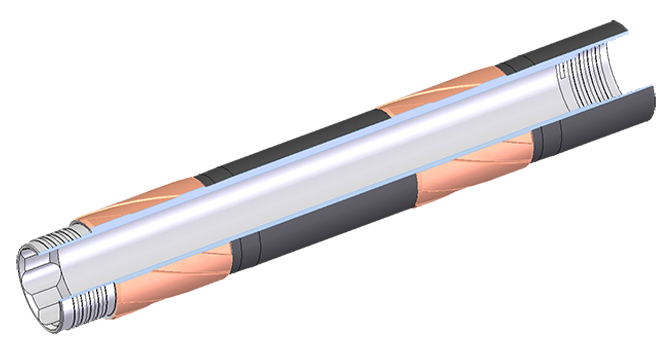

The armour coating of the steel body of a reaming shell is recommended when drilling in highly abrasive formations. The inclusion of these hard-metal strips aid in the prevention of premature erosion of the steel tool body. In most cases, three equally spaced strips are applied to the outside diameter of the steel tool body. The approximate dimensions of each strip are 12 mm (0.50 inch) wide by 0.5 mm (0.02 inch) thick. The length of the strips varies according to the type of tool and typically covers the area shown in the illustration below.

The hard-metal strips are composed of micron-sized tungsten-carbide particles that are suspended in a metal alloy. They are applied using a plasma spray technique. Due to the elevated fusion temperatures that are required for this process, the application of armour coating on some thin-wall reaming shells is not possible.

Armour coating is provided on request only. Pricing for this option varies by reaming shell type. Please contact the Dimatec sales team for a quotation.