This category of products is intended for use in wireline core barrel assemblies (and drill strings) in cases where it is necessary to minimize the degree of drill hole angular deviation in target or deep hole drilling situations. The increased stability that these tools provide will result in less vibration, a straighter drill hole and better core recovery.

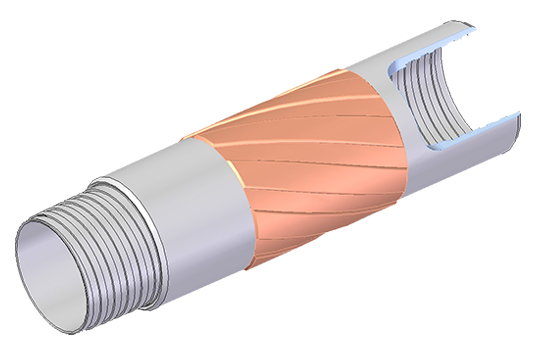

These are diamond set tools that are used in place of the adapter coupling on wireline core barrel assemblies in the AWL (Ø 48.0 mm) to PWL (Ø 122.6 mm) size range. Unlike an adapter coupling however, the gauge ring on these tools is set to full hole gauge diameter. The purpose of the backend reamer is to provide additional stabilization behind the core barrel outer tube in straight-hole drilling applications.

All Dimatec backend reamers are manufactured using the same materials as our RS-5 reaming shells. As such, they are suitable for use in all formation conditions ranging from broken and abrasive to consolidated and non-abrasive.

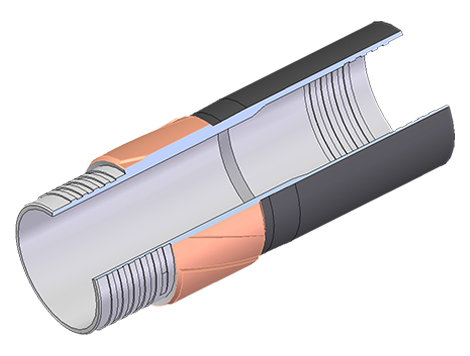

These tools are used at the back end of the core barrel assembly in place of conventional blank or plasma coated adapter couplings. They feature matrix body gauge rings that have been set exclusively with tungsten-carbide particles. As such, these tools will not ream the hole like a diamond set tool would, but rather act as a bearing to stabilize the back end of the core barrel assembly within the drill hole.

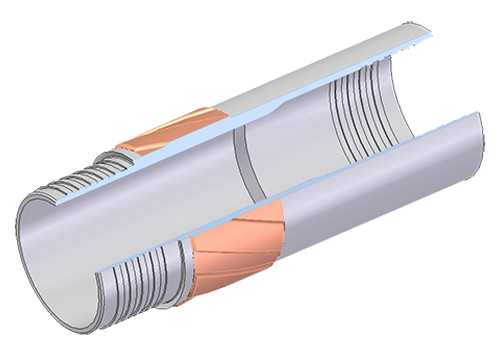

These tools are used at the back end of the core barrel assembly in place of conventional blank or plasma coated locking couplings. They feature matrix body gauge rings that have been set exclusively with tungsten-carbide particles. As such, these tools will not ream the hole like a diamond set tool would, but rather act as a bearing to stabilize the back end of the core barrel assembly within the drill hole. Dimatec’s carbide locking couplings are available with or without a locking tang on the pin thread connection, depending on customer preference.

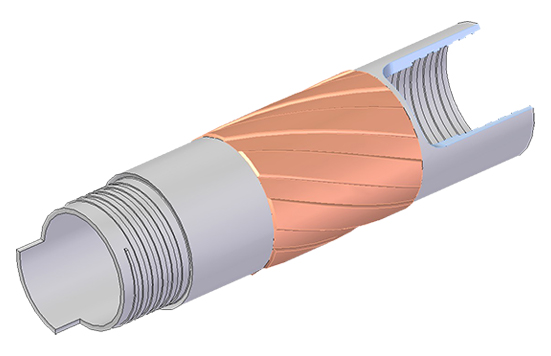

These tools are inserted into a wireline drill string at regularly spaced intervals to assist in keeping the drill string from flexing in a hole with a severely inclined orientation. They feature matrix body gauge rings that have been set exclusively with tungsten-carbide particles. As such, these tools will not ream the hole like a diamond set tool would, but rather act as a bearing to stabilize the drill string in the inclined drill hole.