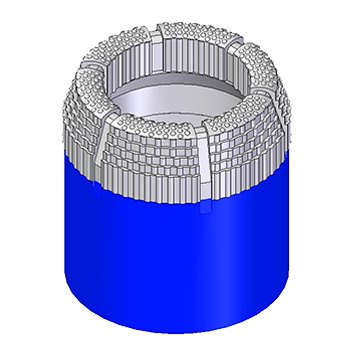

As the name suggests, these bits are set with a single layer of natural industrial drill diamond on the working surfaces of the bit crown in a predetermined pattern. The diamonds are embedded in a powdered metal matrix body that is fused to a steel tool body. This metal bond is extremely tough and wear resistant as its function is to securely hold the diamonds in place throughout the operational life of the bit.Surface-set diamond bits are recommended for use when drilling medium-soft to soft formations that are not drilled effectively by impregnated diamond bits or by bits that have been set with thermally stable polycrystalline (TSP) elements.

The most common profile and standard for surface-set core bits with kerf widths of 10mm (0.39 inch) or less. Recommended for use in a wide range of soft to hard formations. Particularly well suited for use in fractured formations.

Used primarily on medium to wide kerf wireline surface-set core bits in medium-hard formations. Provides good stabilization and will often yield a better penetration rate than the Semi-Round profile. Not recommended for use in heavily fractured formations. Offered in the diamond size ranges of 10, 15, 25 and 50 SPC only.

The size of diamonds used in surface-set bits is described as the number of stones per carat (SPC). The general rule for selecting the appropriate diamond size is that the harder the rock, the smaller the diamond.

As the diamonds that are used in surface-set bits are naturally occurring, they fall into a broad range of sizes. The SPC sizes that are referred to in describing Dimatec’s surface-set drill bits are actually nominal values that represent a fixed range of SPC sizes. These ranges are defined in the table below:

|

Dimatec Diamond |

Actual Number of |

Relative |

|

4 / 5 |

4 to 5 |

Largest |

|

6 / 8 |

6 to 8 |

– |

|

10 |

9 to 12 |

– |

|

15 |

13 to 20 |

– |

|

25 |

21 to 35 |

– |

|

50 |

36 to 60 |

Smallest |

A whole-stone grade of high quality natural drill diamond with stones that are octahedral or dodecahedral in shape with no internal fissures or cracks. Recommended for use when drilling igneous and harder sedimentary formations.

A processed grade of medium quality natural drill diamond with stones that are approximately spherical in shape. Their surface texture may exhibit some irregularities but are free from any internal fissures or cracks. Recommended for use when drilling sedimentary formations.

These stones are sometimes referred to as “black diamond”. They are an opaque grey/black coloured aggregate of diamond crystals, graphite and amorphous carbon. They naturally occur as relatively large, irregularly shaped crystalline structures that are mechanically split into angular shapes with desired particle sizes. Normally, individual carbonado crystals are sized in the range of 10 stones per carat (SPC) or larger. Bits that are set with carbonado crystals are particularly well suited for use in drilling softer formations or hard/soft blended formations such as Serpentine.

The information contained in this section is provided as a basic technical guide for the field application of Dimatec core drilling bits. To use these products successfully, it is necessary for the driller to provide some control over the three primary operating parameters which are:

The data provided here is intended as a basic guideline for the selection of the appropriate tools for your job and the normal operating requirements for their application. As drilling conditions and the capabilities of drilling equipment vary considerably from site to site, it is impossible to define absolute application recommendations. Some experimentation on the part of the user may be required as operating parameter values outside of the ranges suggested here may be applicable to your particular conditions. Technical support is available by contacting Dimatec directly.